Products

-

Medical Oxygen Generator, medical oxygen making equipment, medical oxygen making machine

Medical oxygen generator with pressure swing adsorption (PSA) technology as the foundation, to extract oxygen from the air of the new equipment, the use of molecular sieve physical adsorption and desorption technique in molecular sieve oxygen generator in loading, when the pressure in the air can be nitrogen adsorption, the remaining unabsorbed oxygen is collected, become namely after purification treatment of high purity oxygen. The specific working process is that the compressed air is purified by the air purification dryer and then enters the adsorption tower through the switching valve. In the adsorption tower, nitrogen is adsorbed by molecular sieve, oxygen is accumulated at the top of the adsorption tower into the oxygen storage tank, and then through the odor removal, dust removal filter and sterilization filter filter is qualified medical oxygen. The main components are: air tank, air compressor, cold drying machine, oxygen host, oxygen tank and so on.

-

Pressure swing adsorption nitrogen / oxygen production structure process

PSA nitrogen generator is used as pressure swing adsorption principle and high-quality carbon molecular sieve is used as adsorbent to obtain nitrogen directly from compressed air. A complete installation requires an air compressor, refrigerated air dryer, filter, air tank, nitrogen generator and gas buffer tank. We provide complete installation, but each component, and other optional supplies such as booster, high-pressure compressor or gas station can also be purchased separately.

-

Principle of PSA nitrogen production

Carbon molecular sieve can simultaneously adsorb oxygen and nitrogen in the air, and its adsorption capacity also increases with the increase of pressure, and there is no obvious difference in the equilibrium adsorption capacity of oxygen and nitrogen under the same pressure. Therefore, it is difficult to achieve effective separation of oxygen and nitrogen only by pressure changes. If the adsorption velocity is further considered, the adsorption properties of oxygen and nitrogen can be effectively distinguished.

-

PSA Nitrogen Generator Skid full sets supplier

PSA Nitrogen generator is used as the principle of pressure swing adsorption, The nitrogen is obtained from compressed air directly by using high quality carbon molecular sieve as adsorbent.

A full installation requires air compressor, refrigerated air dryer, filters, air tank, nitrogen generator and gas buffer tank.

We supply full installations but each component, and other optional supply like boosters, high pressure compressors or filling stations can also be bought separately.

-

Carbon carrier purification unit

+Good stability, Oxygen content is strictly controlled below 5ppm.

+High purity, Nitrogen purity≥99.9995%.

+Low water content, atmospheric dew point≤-60℃.

+No hydrogen, The process is suitable for hydrogen and oxygen with strict requirements. -

Nitrogen Purification Equipment With Hydrogenation

Purification process is combined with two kinds of high efficient catalysts, Hydrodeoxygenation at normal temperature,Removing excess hydrogen(When there is a requirement for hydrogen),The high purity nitrogen were obtained through purification process Removal of water and impurity.

Technical Characteristics

+ Automatic control of hydrogenation and high automation, Safe and reliable.

+ Using high efficient catalysts, Advanced technology and stable performance.

+ Using safe and reliable control elements , operate reliably.

+ Intelligent interlocking and emptying, a variety of fault alarm, Users find and solve problems in time.

+ Dehydrogenation at normal temperature,no activation,wide range of deoxgenation. -

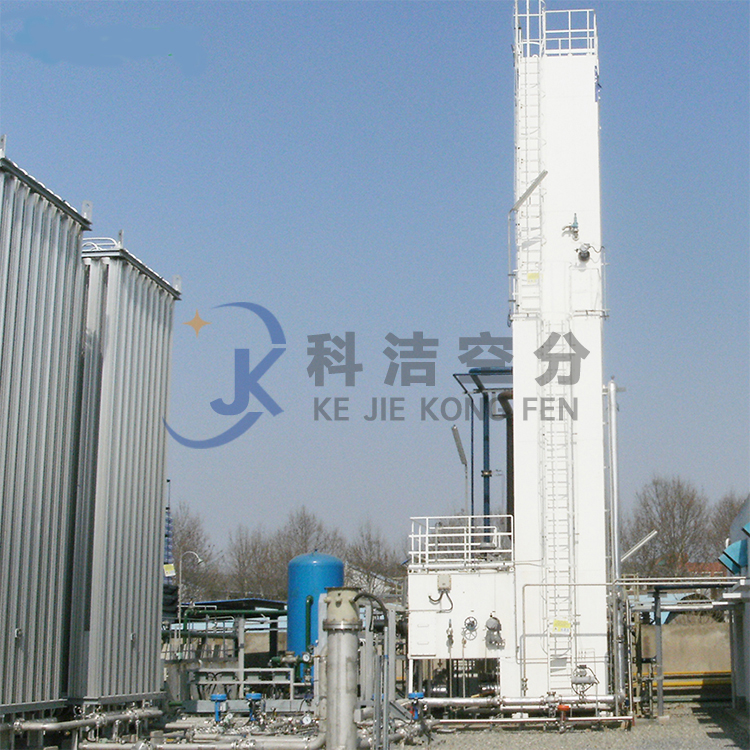

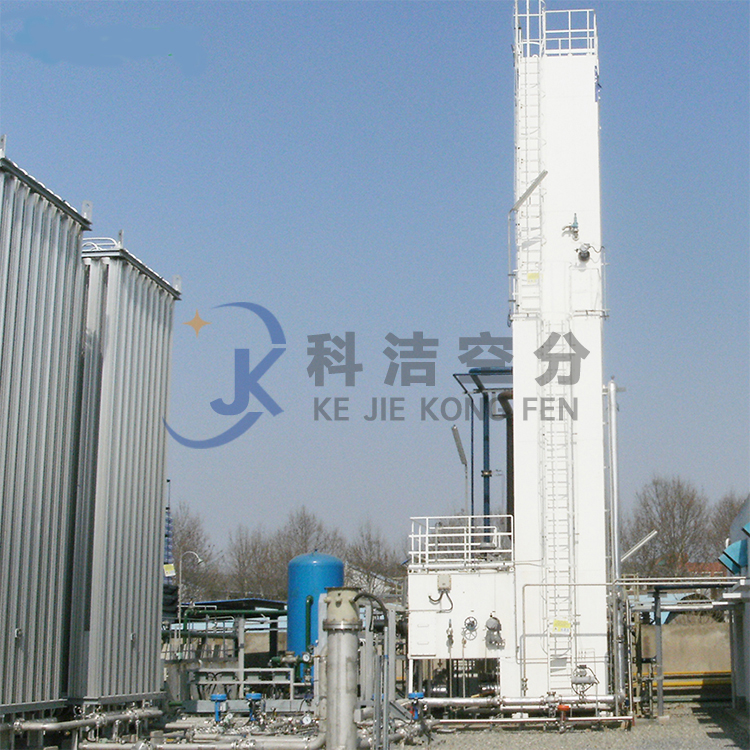

Air separation, cryogenic air separation, cryogenic gas separation

The cryogenic oxygen production & oxygen&nitrogen production process introduces a low-pressure process into the air separation equipment, which reduces the energy consumption of the air separation and improves the safety of operation. Corresponding chemical software is used in process calculation and unit equipment design for process distillation calculation and structure calculation to ensure advanced and reliable equipment.

-

Combined Low dew point Compressed air drier

Capacity: 1~500Nm3/min

Operationg pressure: 0.2~1.0MPa(can provide1.0~3.0MPa)

Inlet air Temperature: ≤45℃(Min5℃)

Dew Point: ≤ -40℃~-70℃(at normal pressure) -

Waste heat regeneration dryer

Waste heat regeneration dryer is a new type of adsorption dryer, which belongs to variable temperature and pressure swing adsorption. It directly heats and regenerates the desiccant by using the heat of high-temperature exhaust of air compressor, so that the adsorbent can be completely regenerated. Therefore, it can make full use of its own energy and has energy-saving effect.

-

Industrial Portable Heatless Adsorption Air Compressed Dryer For Sale

The heatless adsorption compressed air dryer (no heat dryer) is an adsorption drying device. Its function is to remove the moisture in the air through the principle of pressure swing adsorption, so as to achieve the purpose of drying air.

-

Micro–Heat Compressed Air Dryer

The micro-heat regenerative adsorption air dryer (micro-heat dryer) is R & D products by used to absorb two kinds of advantages, such as micro-heat regeneration and heatless regeneration.

-

Refrigerated Compressed Air Dryer

widely used in metallurgical coal, power electronics, petrochemical, biological medicine, tire rubber, textile chemical fiber, grain depot, food preservation and other industries