Leading Manufacturer for Micro Freeze Dryer - Micro–Heat Compressed Air Dryer – Kejie

Leading Manufacturer for Micro Freeze Dryer - Micro–Heat Compressed Air Dryer – Kejie Detail:

Product Details

The ability to adsorb water by a desiccant, and the compressed air is dried by the principle of variable temperature and pressure swing adsorption. The regenerated gas can be used to regenerate desiccant after raising the temperature, which not only improves the regeneration effect, but also reduces the consumption of regenerated gas.

The micro-heat regenerative adsorption Air Dryer (micro-heat Dryer) is a kind of R & D product which absorbs the advantages of micro-heat regenerative and non-heat regenerative, and can reduce the consumption of regenerative gas. Using the desiccant water adsorption capacity, the use of temperature and Pressure swing adsorption principle to dry Compressed air. The regenerated gas can be used as the regenerative desiccant after the temperature is raised, which not only improves the regenerative effect, but also reduces the consumption of the regenerative gas. The micro heat regenerative dryer uses the low dew point Compressed air provided by this machine to desorb and regenerate the adsorbent. It has no definite requirement for the temperature of gas generation, but it is generally far below the minimum desorption temperature required for the “Variable temperature adsorption”of adsorbents, so in essence, “Micro-heat”regeneration is still within the scope of PSA, the purpose of heating regeneration gas is to reduce the consumption of regeneration gas. Secondly, as the regeneration gas with low dew point has provided the necessary environmental conditions for the desorption of the adsorbent, the limited increase of the temperature of the regeneration gas can speed up the desorption rate is not important for the dryer. However, the exhaust temperature of the regenerated exhaust gas is directly related to the consumption of the regenerated gas. The higher the temperature of the regenerated exhaust gas, the more water vapor it can absorb.

Technical Indexs

| 1 | capacity: | 10-20000Nm3/min |

| 2 | Nitrogen purity: | 299. 9995%. |

| Nitrogen Pressure. | 0.1-0.7MPa(adjustable) | |

| 3 | Oxygen content | ≤5ppm |

| 4 | Dust content: | ≤0.01um |

| 5 | Dew point: | ≤-60°C. |

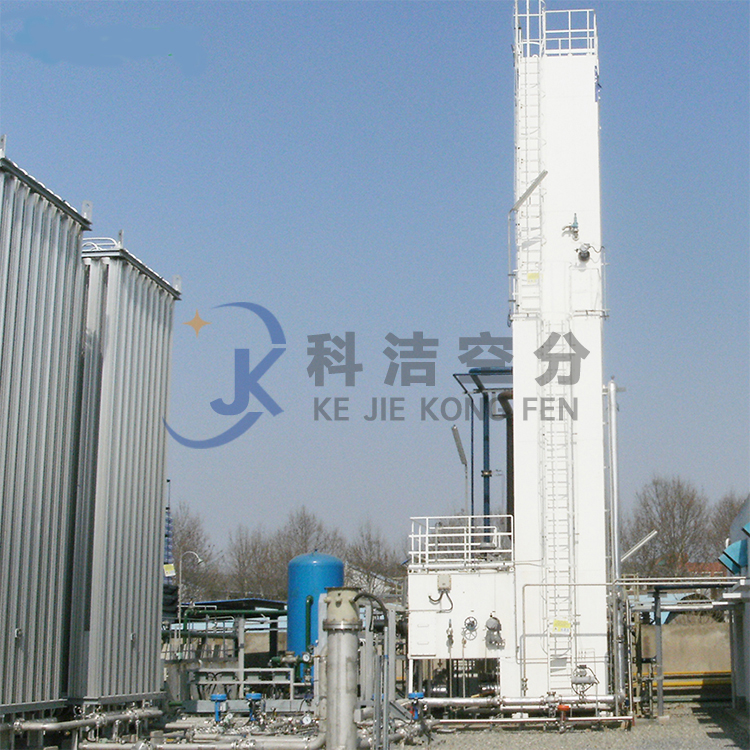

Product detail pictures:

Related Product Guide:

Our items are commonly identified and trusted by customers and may fulfill continuously switching economic and social wants of Leading Manufacturer for Micro Freeze Dryer - Micro–Heat Compressed Air Dryer – Kejie , The product will supply to all over the world, such as: Armenia, Canberra, Turkey, We follow superior mechanism to process these goods that ensure optimum durability and reliability of the goods. We follow latest effective washing and straightening processes that enable us to supply unmatched quality of items for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.