Hot sale Cryogenic Separation Process – Air separation, cryogenic air separation, cryogenic gas separation – Kejie

Hot sale Cryogenic Separation Process – Air separation, cryogenic air separation, cryogenic gas separation – Kejie Detail:

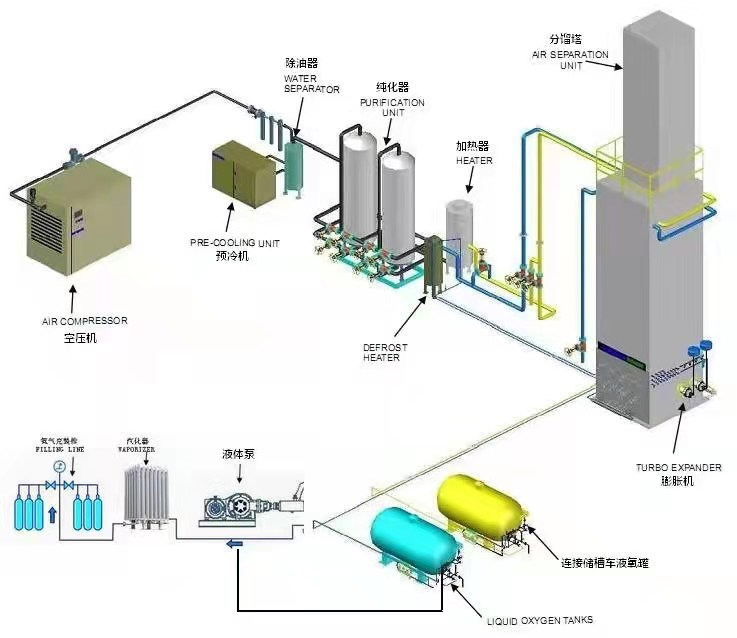

Process

1、Air Compressor: Air be compressed to 0.5-0.7Mpa by air compressor

2、Pre-cooling: The air is pre-cooled to 5-10℃ in the pre-cooling unit, and the moisture is separated.

3、Air purification system:Removing the remained moisture, carbon dioxide and hydrocarbons of compressed air in the molecular sieve purifier;

4、Air expansion:The air expands and cools in the turbo expander and provides the cooling capacity required by the device

5、Heat Exchange:The air exchanges heat with the refluxing oxygen, nitrogen, and dirty nitrogen in the heat exchanger of the fractionation tower, and is cooled close to the liquefaction temperature, and the refluxed oxygen, nitrogen, and dirty nitrogen are repeatedly heat exchanged to the ambient temperature;

6、Cooling:Cooling the liquid air and liquid nitrogen before the throttling of the nitrogen in the chiller.

7、Distillation:The air is rectified and separated in the rectification tower, and the product nitrogen is obtained at the top of the upper tower, and the product oxygen is obtained at the bottom of the upper tower.

In order to meet the needs of the market, in addition to the production of conventional external compression air separation equipment, the company has also developed a series of internal compression air separation processes, which reduces the installation workload and equipment maintenance of the complete set of equipment.

The company designed and developed a skid-mounted purification system to minimize on-site piping installation time.

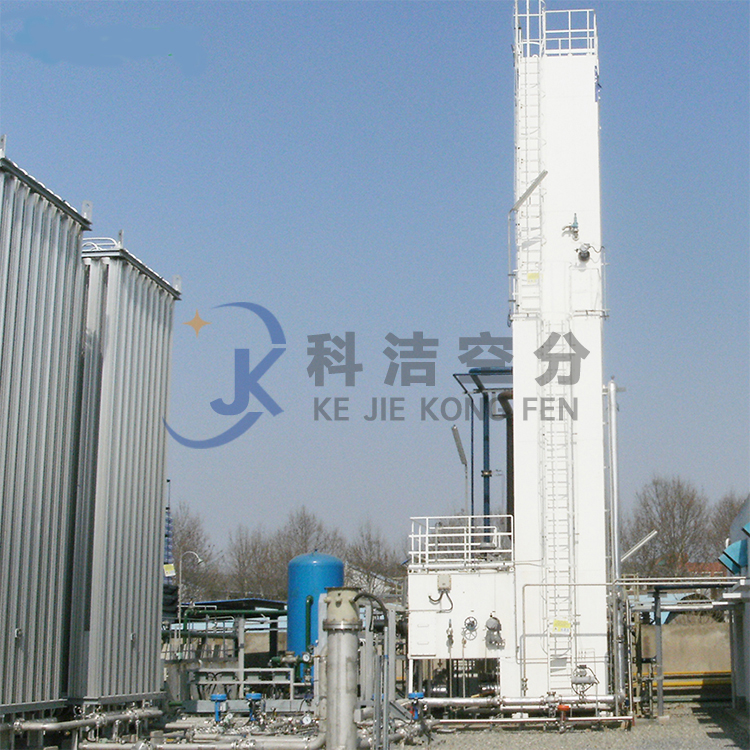

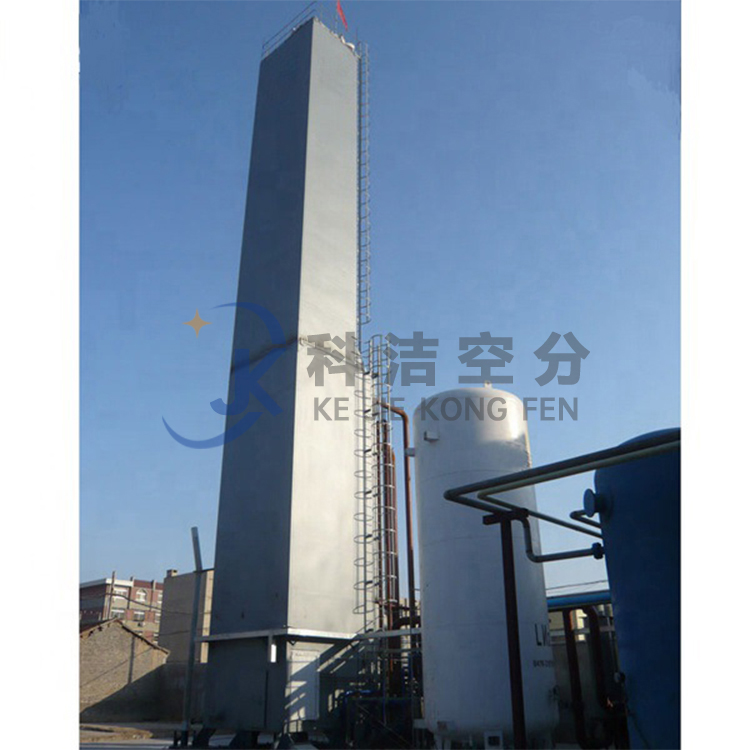

Product detail pictures:

Related Product Guide:

Persisting in "High quality, Prompt Delivery, Aggressive Price", now we have established long-term cooperation with consumers from equally overseas and domestically and get new and old clients' large comments for Hot sale Cryogenic Separation Process – Air separation, cryogenic air separation, cryogenic gas separation – Kejie , The product will supply to all over the world, such as: Angola, Montreal, Albania, With the enterprising spirit of" high efficiency, convenience, practicality and innovation", and in line with such serving guidance of "good quality but better price, " and "global credit", we've been striving to cooperate with the automobile parts companies all over the world to make a win-win partnership.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.