Plateau oxygen generator – tunnel oxygen generator

Nitrogen molecules have a faster diffusion rate in the micropores of zeolite molecular sieve, and oxygen molecules have a slower diffusion rate. The diffusion of water and carbon dioxide in compressed air is similar to that of nitrogen. Finally, oxygen molecules are enriched from the adsorption tower. Pressure swing adsorption oxygen production uses the selective adsorption characteristics of zeolite molecular sieve, adopts the cycle of pressurized adsorption and decompression desorption, and makes the compressed air enter the adsorption tower alternately to realize the separation of oxygen and nitrogen, so as to continuously produce high-purity and high-quality oxygen.

PSA oxygen generator adopts high-quality zeolite as adsorbent according to the principle of pressure swing adsorption. Under a certain pressure, oxygen is extracted from the air, purified and dried compressed air, and pressurized adsorption and decompression desorption are carried out in the adsorber. Due to the aerodynamic effect, the diffusion rate of nitrogen in the micropores of zeolite molecular sieve is much higher than that of oxygen. Nitrogen is preferentially adsorbed by zeolite molecular sieve, and oxygen is enriched in the gas phase to form finished oxygen. Then, after decompression to atmospheric pressure, molecular sieve desorbs the adsorbed nitrogen and other impurities to realize regeneration. Generally, two adsorption towers are set in the system, one for adsorption and oxygen production, and the other for desorption and regeneration. The PLC program controller controls the opening and closing of the pneumatic valve to make the two towers circulate alternately, so as to achieve the purpose of continuous production of high-quality oxygen.

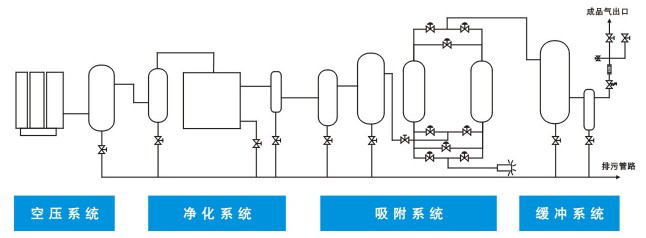

System Flow